| Model | Nominal Pressure (Mpa) | Max Discharge Flow(lpm) | Nominal Capacity (L) | H(mm) | Dimensions(mm) | Weight (kg) | |||||||||||

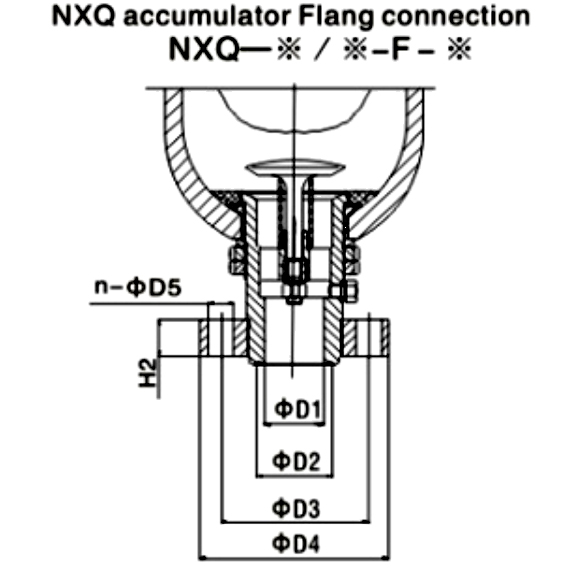

| Threaded Connection | Flange Connection | Threaded Connection | Flange Connection | DM | ∅D1 | ∅D2 | ∅D3 | ∅D4 | ∅-D5 | ∅D6 | H1 | H2 | D | ||||

| NXQ※-L0.4/※-L-※ | 10/20/31.5 | 1 | 0.4 | 250 | M27*2 | 32 (32*3.1) | 52 | 89 | 3 | ||||||||

| NXQ※-L0.63/※-L-※ | 0.63 | 320 | 3.5 | ||||||||||||||

| NXQ※-1/※-L-※ | 1 | 315 | 114 | 5.5 | |||||||||||||

| NXQ※-1.6/※-L/F-※ | 3.2 | 6 | 1.6 | 355 | 370 | M42*2 | 40 | 50 (50*3.1) | 97 | 130 | 6-∅17 | 50 (50*3.1) | 66 | 25 | 152 | 12.5 | |

| NXQ※-2.5/※-L/F-※ | 2.5 | 420 | 435 | 15 | |||||||||||||

| NXQ※-4/※-L/F-※ | 4 | 530 | 545 | 18.5 | |||||||||||||

| NXQ※-6.3/※-L/F-※ | 6.3 | 700 | 715 | 25.5 | |||||||||||||

| NXQ※-10/※-L/F-※ | 6 | 10 | 10 | 660 | 685 | M60*2 | 50 | 70 (70*3.1) | 125 | 160 | 6-∅22 | 70 (70*3.1) | 85 | 32 | 219 | 41 | |

| NXQ※-16/※-L/F-※ | 16 | 870 | 895 | 53 | |||||||||||||

| NXQ※-20/※-L/F-※ | 20 | 1000 | 1025 | 62 | |||||||||||||

| NXQ※-25/※-L/F-※ | 25 | 1170 | 1195 | 72 | |||||||||||||

| NXQ※-32/※-L/F-※ | 32 | 1410 | 1435 | 82 | |||||||||||||

| NXQ※-40/※-L/F-※ | 40 | 1690 | 1715 | 104 | |||||||||||||

| NXQ※-50/※-L/F-※ | 50 | 2040 | 2065 | 118 | |||||||||||||

| NXQ※-20/※-L/F-※ | 10 | 15 | 20 | 690 | 715 | M72*2 | 60 | 80 (80*3.1) | 150 | 200 | 6-∅26 | 80 (80*3.1) | 105 | 40 | 299 | 92 | |

| NXQ※-25/※-L/F-※ | 25 | 780 | 810 | 105 | |||||||||||||

| NXQ※-40/※-L/F-※ | 40 | 1050 | 1080 | 135 | |||||||||||||

| NXQ※-50/※-L/F-※ | 50 | 1240 | 1270 | 148 | |||||||||||||

| NXQ※-63/※-L/F-※ | 63 | 1470 | 1500 | 191 | |||||||||||||

| NXQ※-80/※-L/F-※ | 80 | 1810 | 1840 | 241 | |||||||||||||

| NXQ※-100/※-L/F-※ | 100 | 2190 | 2220 | 290 | |||||||||||||

| NXQ※-63/※-L/F-※ | 15 | 20 | 63 | 1188 | 1203 | M80*3 | 80 | 95 (95*3.1) | 170 | 230 | 6-∅26 | 90 (90*3.1) | 115 | 45 | 351 | 191 | |

| NXQ※-80/※-L/F-※ | 80 | 1418 | 1433 | 228 | |||||||||||||

| NXQ※-100/※-L/F-※ | 100 | 1688 | 1703 | 270 | |||||||||||||

| NXQ※-125/※-L/F-※ | 125 | 2008 | 2023 | 322 | |||||||||||||

| NXQ※-160/※-L/F-※ | 160 | 2478 | 2493 | 397 | |||||||||||||

| NXQ※-100/※-L/F-※ | 20 | 25 | 100 | 1315 | 1360 | M100*3 | 80 | 115 (115*3.1) | 220 | 225 | 8-∅26 | 115 (115*3.1) | 115 | 50 | 426 | 441 | |

| NXQ※-160/※-L/F-※ | 160 | 1915 | 1960 | 552 | |||||||||||||

| NXQ※-200/※-L/F-※ | 200 | 2315 | 2360 | 663 | |||||||||||||

| NXQ※-250/※-L/F-※ | 250 | 2915 | 2960 | 786 | |||||||||||||

Petrochemical Equipment

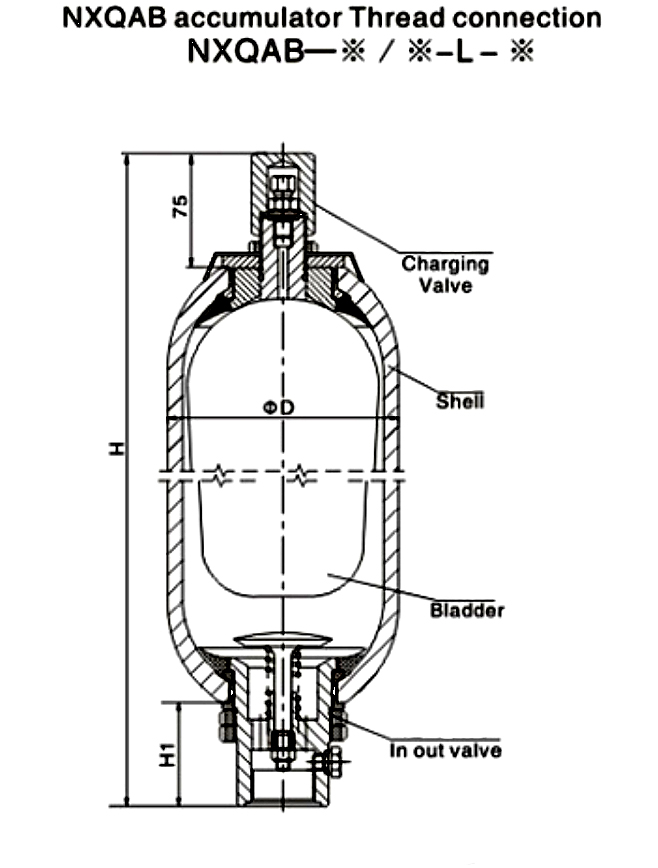

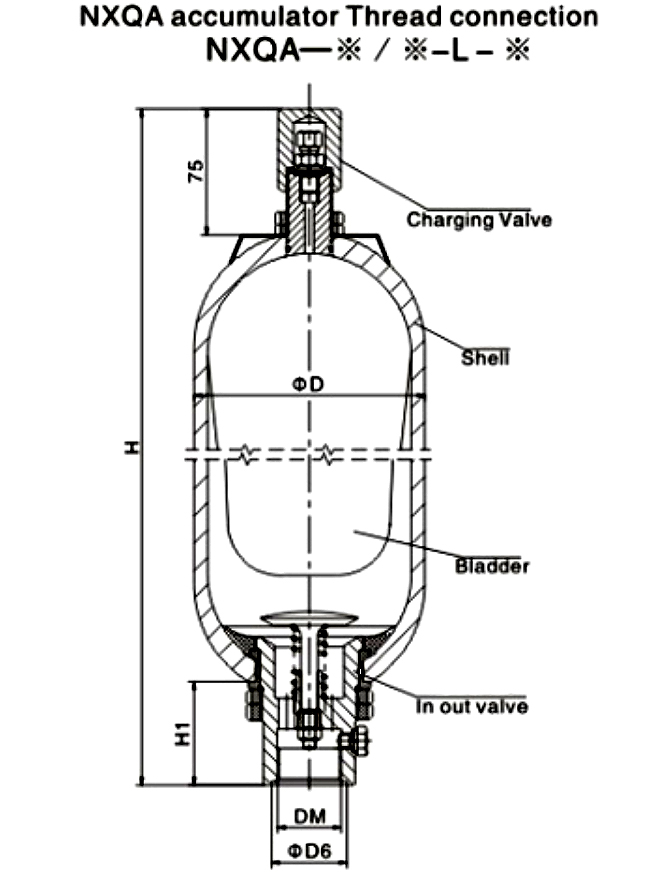

| NXQ | ※ | ※ | / | ※ | ※ | ※ |

| Bladder Accumulator | Structure Type Type A:Small bore Type AB:Large bore | Nominal Capacity 0.4-250L | Nominal Pressure 10Mpa 20Mpa 31.5Mpa | Connection Method L:Threaded connection F:Flange connection | Working Medium Y:Hydraulic oil R:Emulsion EG:Water glycol |

Ship

Metallurgy

Metallurgy

Engineering Machinery

Hydraulic Machine Tool

Genset

Aviation

Craftsman Spirit, Ingenuity Quality. Support non-standard customization, one-to-one service from engineers. • Energy Storage • Stabilize Pressure • Reduce Power Consumption • Compensate For Leakage Losses Note: This product can only be filled with nitrogen (or inert gas) It is forbidden to fill oxygen and flammable and explosive gases.

Craftsman Spirit, Ingenuity Quality. Support non-standard customization, one-to-one service from engineers. • Energy Storage • Stabilize Pressure • Reduce Power Consumption • Compensate For Leakage Losses Note: This product can only be filled with nitrogen (or inert gas) It is forbidden to fill oxygen and flammable and explosive gases.

Water Conservancy Engineering

Packaging Machinery

Agricultural Machinery

Packaging Machinery