| Model | Rated Flow (L/min) | Working Pressure (MPa) | Cooling Capacity (KW) | Fan Power(W) | Inlet&Outlet Thread | L*W*H (mm) | Net Weight (KG) | |||

| 220V | 380V | 12V | 24V | |||||||

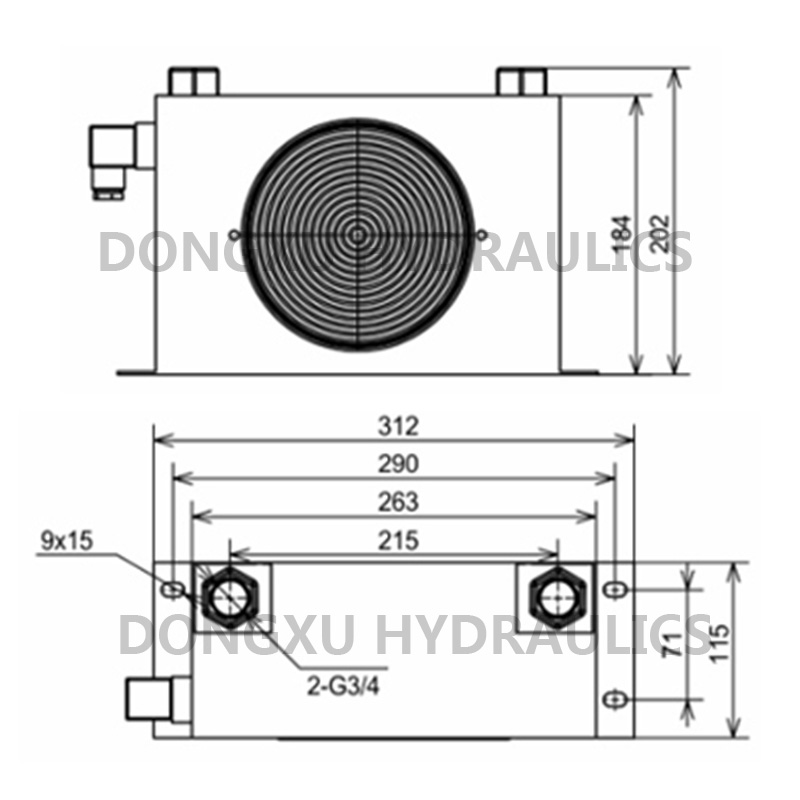

| AH0608T-CA | 60 | ≤2.0 | 1.7 | 35 | 35 | 16 | 16 | G¾" | 313*115*202 | 4 |

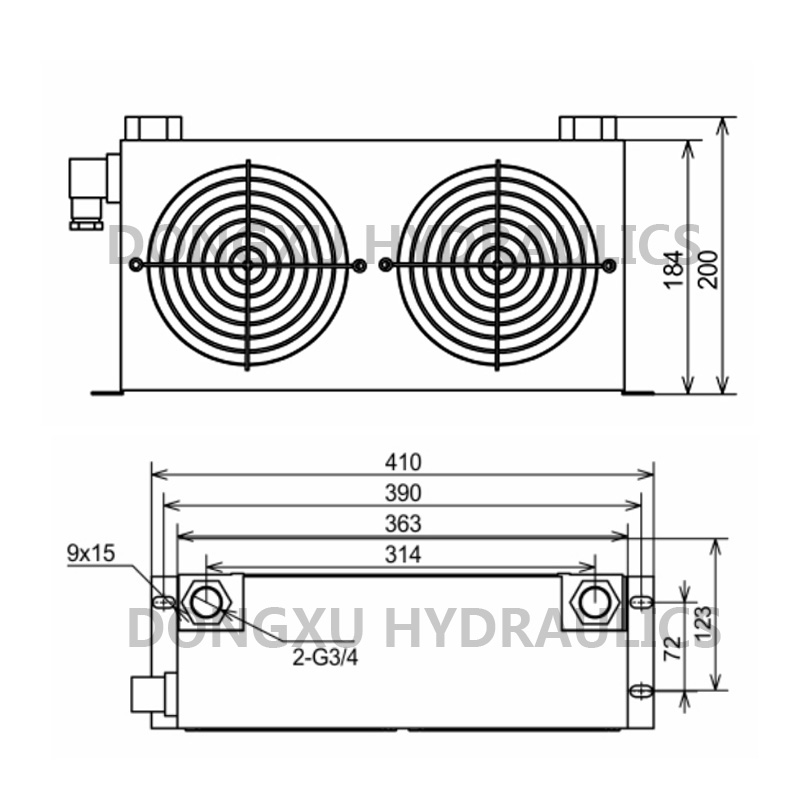

| AH0608TL-CA | ≤2.0 | 3.2 | 2*35 | 2*35 | 2*16 | 2*16 | 406*123*200 | 6 | ||

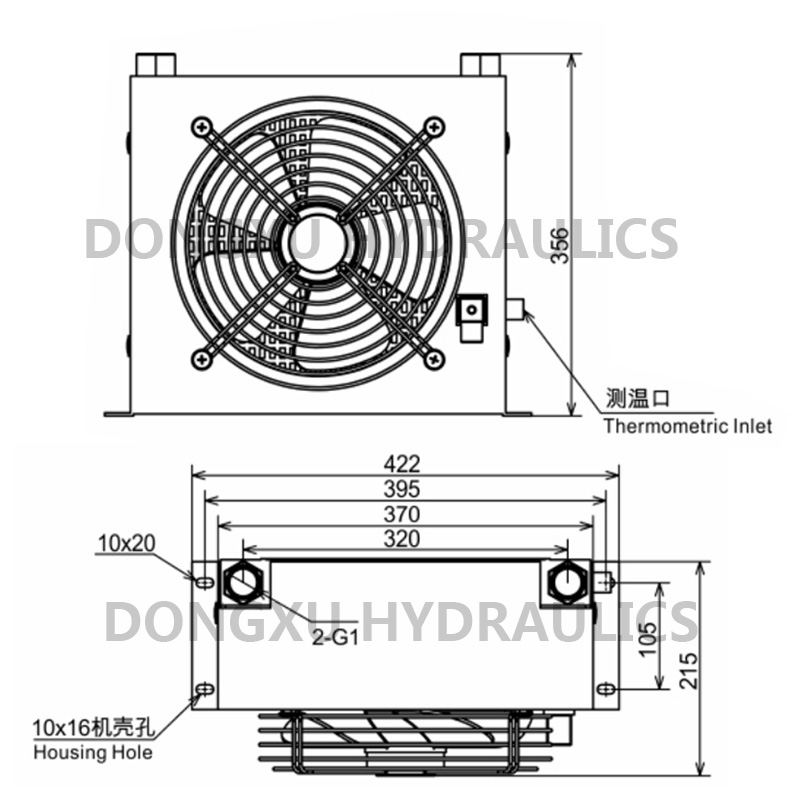

| AH1012T-CA | 100 | ≤2.0 | 5.6 | 50 | 60 | 80 | 80 | G1" | 395*215*356 | 10 |

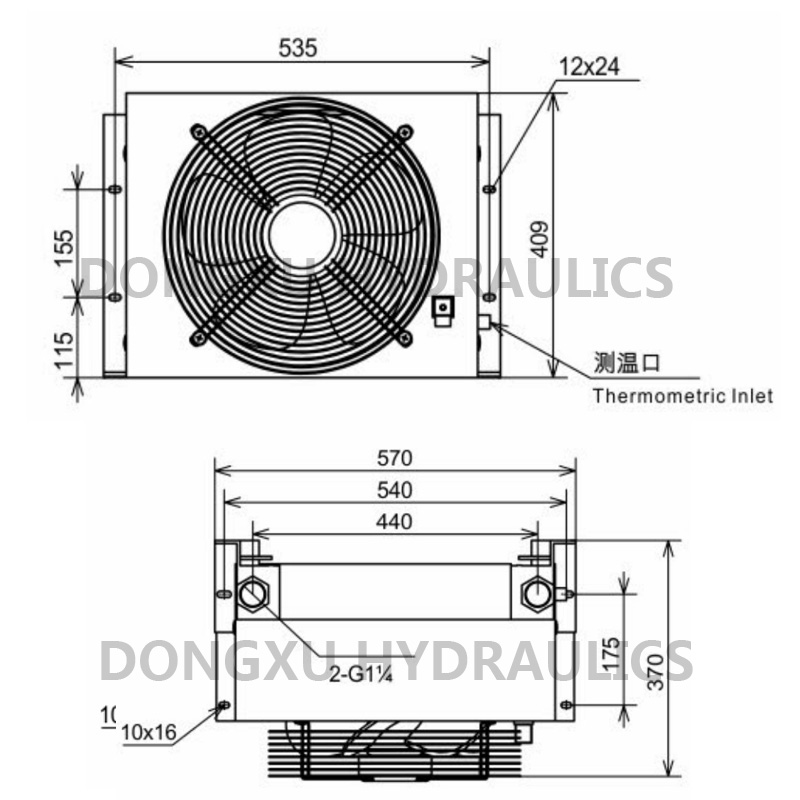

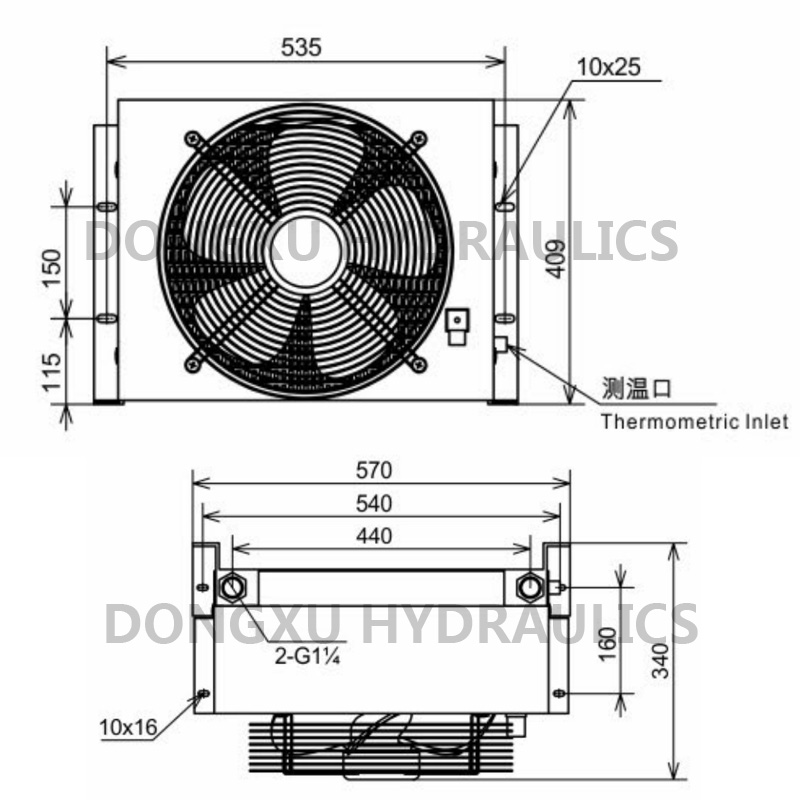

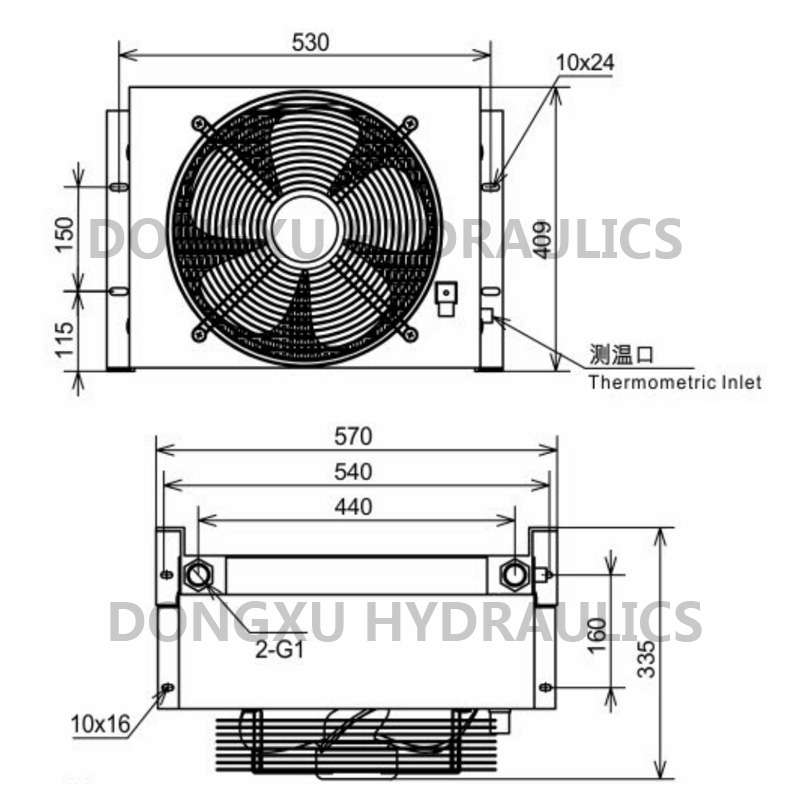

| AH1417T-CA | 150 | ≤2.0 | 14.5 | 129 | 129 | 120 | 120 | 570*335*409 | 20 | |

| AH1470T-CA | 200 | ≤2.0 | 18.2 | 129 | 129 | 120 | 120 | G1¼" | 570*340*409 | 22 |

| AH1490T-CA | 250 | ≤2.0 | 24 | 129 | 129 | 120 | 120 | 570*370*409 | 26 | |

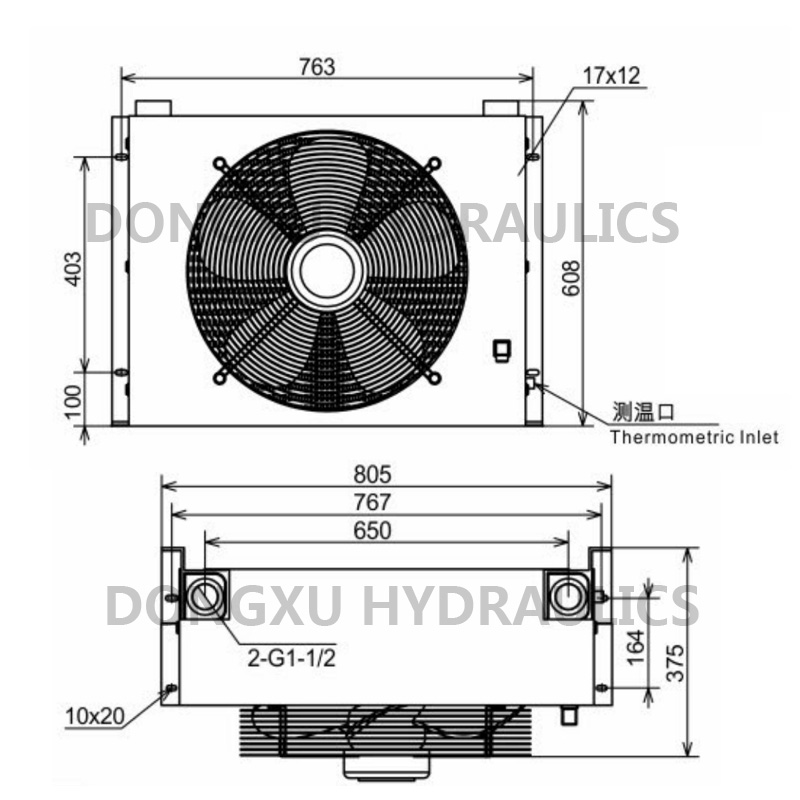

| AH1680T-CA | 300 | ≤2.0 | 30 | 380 | 414 | / | / | G1½" | 805*375*608 | 49 |

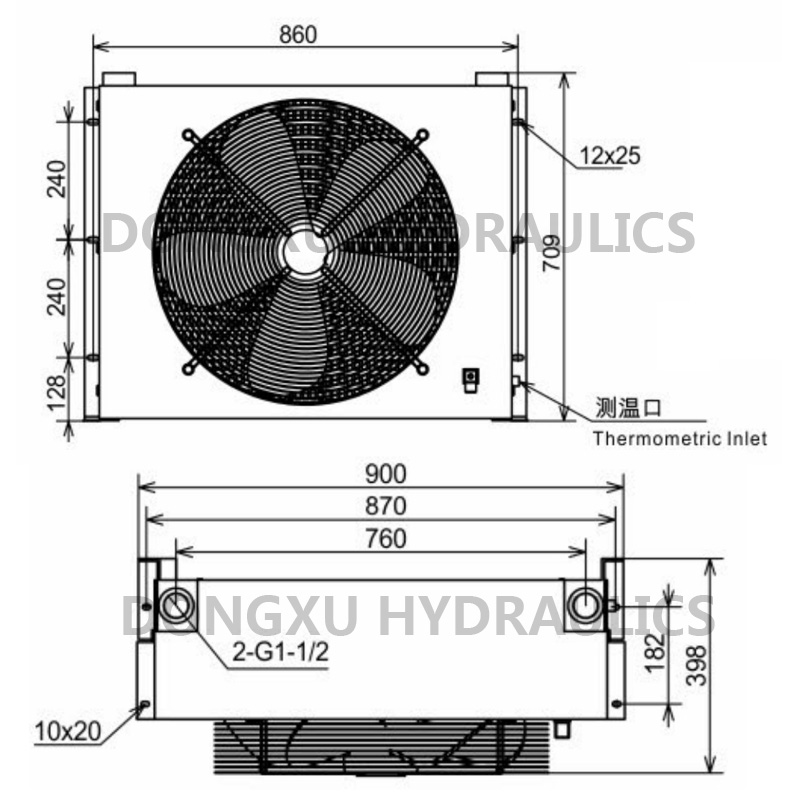

| AH2431T-CA | 450 | ≤2.0 | 52 | 666 | 780 | / | / | 900*398*709 | 67 | |

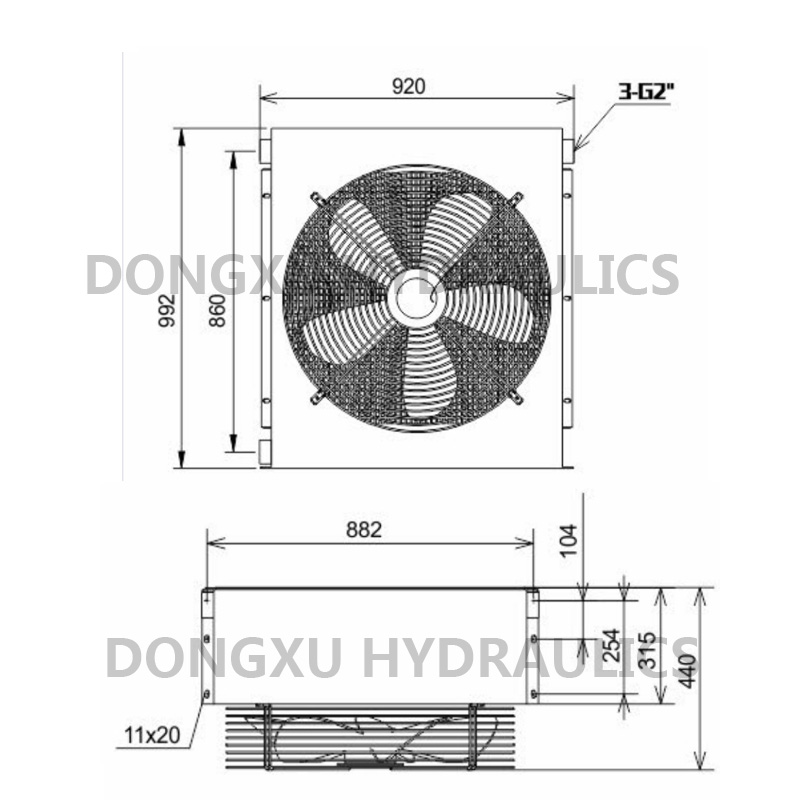

| AH3818T-CA | 600 | ≤2.0 | 83 | / | 900 | / | / | G2" | 920*440*992 | 104 |

| Notice: | ||||||||||

| In order to protect the cooler from breaking, the explosion-proof valve or bypass unloading circuit must be installed when the cooler is installed in the oil return circuit. | ||||||||||

Don't corrode aluminum alloys: ① Hydraulic oil ② lubricating oil ③ Water and water-soluble liquids... Water and Glycol Mixtures, please consult us.

Don't corrode aluminum alloys: ① Hydraulic oil ② lubricating oil ③ Water and water-soluble liquids... Water and Glycol Mixtures, please consult us.Construction machinery

Special machinery

Lubrication systems

Tunnels

Port machinery

Hydraulic power stations

Machine tools