Enter the Copper Fin Heat Exchanger, a piece of equipment designed to regulate the temperature of hydraulic fluids within a hydraulic system. This revolutionary piece of equipment is highly sought after by industries such as marine, automotive, and aerospace, where temperature control is essential for the smooth functioning of their hydraulic systems.

But what exactly is a Copper Fin Heat Exchanger? Simply put, it is a device that transfers thermal energy from one fluid to another through conductive materials. In hydraulic systems, the heat exchanger extracts heat from the hydraulic fluid and passes it on to the surrounding air or another fluid. This process ensures that the hydraulic fluid remains within its optimal operating temperature range, preventing damage to your system.

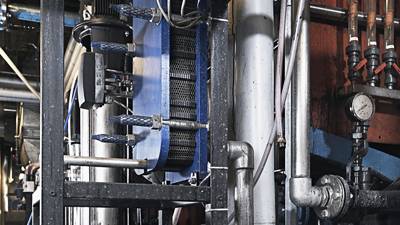

The Copper Fin Heat Exchanger is made of high-quality copper, which is a superior conductor of heat. Copper finned tubes provide exceptional surface area for heat transfer, allowing the heat exchanger to efficiently extract heat from the hydraulic fluid. The fins are designed to increase the surface area for better heat transfer, making the exchanger more effective than traditional designs.

There are several types of Copper Fin Heat Exchangers, including shell-and-tube, plate, and finned-tube. Each of these designs is used in hydraulic systems for different applications. For example, a shell-and-tube Copper Fin Heat Exchanger is commonly used in hydraulic systems with high flow rates, whereas a plate Copper Fin Heat Exchanger is preferred for low flow rates.

Regardless of the type, each Copper Fin Heat Exchanger works towards the same goal, which is to maintain an optimal operating temperature of the hydraulic fluid. This is important, because as mentioned earlier, the viscosity of the fluid increases as the temperature drops. A decrease in viscosity means that the fluid is less efficient at lubricating the various components of the hydraulic system, which can lead to wear and tear.

In summary, the Copper Fin Heat Exchanger is an essential component of any hydraulic system. It ensures that the hydraulic fluid remains at an optimal operating temperature, preventing damage to the system and enhancing performance. Contact your local manufacturer today to learn more about how a Copper Fin Heat Exchanger can benefit your hydraulic system.