Mobile hydraulic equipment is widely used in various industries such as construction, agriculture, and mining. These machines require hydraulic fluid to operate and perform a range of crucial functions. One of the critical conditioning requirements of hydraulic fluid is that it is maintained at an optimal operating temperature. As oil temperature drops, the viscosity of the fluid increases, leading to sluggish and inefficient machine performance. Conversely, high operating temperatures can cause premature fluid degradation, leading to equipment failure. To maintain the optimal oil temperature, mobile hydraulic systems rely on efficient cooling systems, such as hydraulic plate fin heat exchangers.

Hydraulic Plate Fin Heat Exchangers for Mobile Equipment

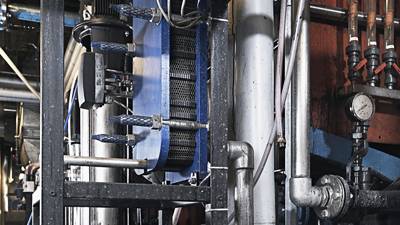

Hydraulic plate fin heat exchangers are one of the most popular types of heat exchangers used in mobile hydraulic systems. These heat exchangers transfer the heat from the hydraulic fluid to another medium such as air or water, which then dissipates it into the environment. The plate fin design consists of a network of thin fins that are arranged in a way to maximize the heat transfer surface area.

One of the significant advantages of hydraulic plate fin heat exchangers is their compact size and lightweight construction. These heat exchangers can fit into small spaces, making them ideal for mobile equipment with limited mounting space. Moreover, the plate fin design enables these heat exchangers to achieve high heat transfer rates even with a small temperature difference between the two mediums.

Optimal Operating Temperature for Hydraulic Fluid

To ensure that a mobile hydraulic system functions optimally, it is crucial to maintain the hydraulic fluid at an optimal operating temperature. The recommended fluid temperature typically ranges between 40°C to 80°C, depending on the application and the fluid type. At this temperature range, the fluid's viscosity is low enough to ensure smooth operation of the hydraulic machine, and the fluid's oxidative stability is high enough to avoid fluid degradation.

Several factors can influence hydraulic fluid temperature, such as ambient temperature, operating cycle, and fluid flow rate. For instance, in hot environments, the fluid temperature can rise quickly, leading to premature fluid degradation and equipment failure. On the other hand, cold environments can cause the fluid's viscosity to increase, leading to sluggish machine performance or even operational failure.

To maintain the optimal fluid temperature, hydraulic systems rely on cooling mechanisms such as hydraulic plate fin heat exchangers. These systems transfer heat from the fluid to another medium, removing excess heat and preventing fluid overheating. Moreover, some hydraulic plate fin heat exchangers come with built-in thermostats to regulate the fluid temperature automatically, ensuring optimal operation in varying ambient conditions.

Conclusion

Mobile hydraulic equipment is ubiquitous in various industries and requires efficient cooling mechanisms to maintain optimal operation. Hydraulic fluid temperature is a critical conditioning requirement that, when not met, can lead to equipment failure or reduced machine performance. Hydraulic plate fin heat exchangers offer an efficient and compact cooling solution for mobile hydraulic systems. These heat exchangers transfer heat from the fluid to another medium and maintain the fluid temperature within the recommended range. To ensure that your mobile hydraulic equipment performs optimally, invest in a reliable hydraulic plate fin heat exchanger, and maintain the optimal operating temperature of the hydraulic fluid.